Membrane Separation Plant

Marcuras is involved in manufacturing and supplying a comprehensive range of Membrane Separation Plant.

These are :

Micro Filtration Plants(MF)

Ultra Filtration Plants(UF)

Nano Filtration Plants(NF)

Reverse Osmosis Plants(RO)

Membrane technology is gaining high importance in the water treatment industry because it is easy to understand and guarantee efficient and environment-friendly purification with a minimal use of chemicals.

Marcuras is involved in manufacturing and supplying of a comprehensive range of reverse osmosis plants, ultra filtration plants, RO plants, UF plants, nano filtration plants, water treatment system, RO systems, containerized water treatment plants, water purification systems etc.

Micro Filtration Plant

Micro-filtration plants can be constructed by using hollow fiber membranes or spiral wound membranes. In case of special aplications it is possible to use ceramic membranes.

Ultra Filtration Plant

Ultra-filtration plants can be constructed by employing hollow fiber membranes or spiral wound membranes. They work with a pressure of about 1-10 bar and they are suitable to separate big molecules present in water. The ultrafiltration plants have established a position in the drinking water sector due to the fact that they filter water to such an extent that it is virtually free of solids. Bacteria, parasites and viruses are not killed off, but entirely removed from the drinking water.

Ultra-filtration plants can be constructed by employing hollow fiber membranes or spiral wound membranes. They work with a pressure of about 1-10 bar and they are suitable to separate big molecules present in water. The ultrafiltration plants have established a position in the drinking water sector due to the fact that they filter water to such an extent that it is virtually free of solids. Bacteria, parasites and viruses are not killed off, but entirely removed from the drinking water.

Nano Filtration Plant

Nano filtration plant are generally constructed by installing hollow fiber membranes or spiral wound membranes. They have a medium-high working pressure (4-30 bar) and they are normally used to reduce water hardness, to recover salts from dying baths, to remove colour and to recover acids and caustic soda.

Reverse Osmosis Plant

Reverse osmosis plants are quite exclusively constructed by installing spiral wound membranes. They work with medium-high pressure depending on the type of application (6 - 80 bar) and they are applied to separate the dissolved salts from aqueous solutions by means of semi-permeable membranes. In this case the dimension of membrane pores are very small so that the resistance to the passage of water is higher.

Reverse osmosis plants are quite exclusively constructed by installing spiral wound membranes. They work with medium-high pressure depending on the type of application (6 - 80 bar) and they are applied to separate the dissolved salts from aqueous solutions by means of semi-permeable membranes. In this case the dimension of membrane pores are very small so that the resistance to the passage of water is higher.

The technology and process involved are relatively simple, membranes representing very fine filters, which act like sieves through which water is either pressed or sucked. Any content, which is larger than the microscopic pores, is separated out and depending on the fineness of the filter, a differentiation is made between micro-, ultra- and nanofiltration. Reverse osmosis is an additional variation, in which only water molecules pass through the membrane.

Marcuras has been using this membrane process in combination with conventional cleaning processes for many years and due to this experience and in-house innovations, has built up a pool of comprehensive expertise. We offer a diversity of membrane processes and selects the best and lowest-cost variation for each application.

Other advantages of our membrane filtration are:

Modular design

Membranes as absolute barriers

Low space requirement

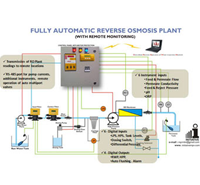

Remote Monitored RO Systems

Our aim is to increase the operational efficiency of the RO Plants and reduce operational/service costs. Real time status parameters of all RO Plants anywhere in India can be done from a single location.

Why Remote Monitoring?

Problems with the Current Systems:

Plant operators are not well versed with the technical aspects of the RO plant and cannot interpret instrument values such as flow, pressure, conductivity and pH.

A site complaint is received only when the flow reduces drastically (or) the plant completely breaks down.

Site Operators do not backwash sand/carbon filters timely nor do they change cartridges when required.

Site Operators may throttle the reject control valve too much to get better permeate flow.

Site Operators may not ensure antiscalant dosing pumps operation

Log books are rarely maintained at site.

Service calls are always an emergency. The cost of providing the service has to borne by the supplier providing the service or any material consumed.

CROWN :

CROWN is a software application, provides central supervisory 'control and monitoring' of water treatment equipment. CROWN communicates to LCU on the site for control operations.

Key Features:

Create / Edit Remote Site configurations (MPV's, Instruments, Digital I/O etc.) & Client details

Simultaneous data logging from various sites using GSM(SMS) technology

Instantly start Backwash/Regeneration Cycles of Remote Sites. Change service/backwash timings as per requirement.

Receives status messages based on three options

Status based on preset time.

On-Demand status

In case of alert conditions at site

Generates SMS alerts in case of critical problems at Site

Generates alerts to service technicians in case of device value is beyond safe operational range. (Ex: Pressure, Conductivity etc)

Provides history of plant operational status, commands issued for a selected site.

Option to export status information to excel sheets.

Provides Graphical summary for instrument readings

Operational summary notifications to concerned persons

Decision Making Table:

| Remote Monitoring System | Manual Operations | |

| Site Break Down | Minimal | High if not monitored |

| Site Maintenance | Minimal | High if not maintained |

| Site Operation Status | Available 24 x 7 | Have to get from site visit |

| Efficient Equipment Usage | Available | Not know until informed |

| Operating More Sites | Easy | Difficult to provide service |